High-Speed Dry Ice Blasting: Eco-Friendly, Efficient Cleaning

Dry ice blasting uses high-speed pellets to clean surfaces by harnessing kinetic energy, effectively removing dirt without abrasive materials or harsh chemicals. This non-toxic, eco-friendly method is safe for both delicate items and industrial surfaces, offering a sustainable alternative to traditional cleaning methods.

Eco-Friendly Benefits of Dry Ice Blasting

Favoured by environmentally conscious industries, dry ice blasting provides a residue-free clean while reducing environmental impact. It’s an ideal solution for businesses committed to sustainable, non-toxic practices.

Thermal shock cleaning uses rapid temperature changes from cold dry ice pellets contacting warmer surfaces to induce a quick shift in temperature. This causes contaminants to become brittle, making them easy to remove without the need for scraping or chemicals. This non-abrasive method preserves the integrity of delicate items while ensuring thorough decontamination.

Safe and Versatile Surface Cleaning

Ideal for a wide variety of surfaces, thermal shock cleaning is safe and effective across industrial, commercial, and delicate applications. It’s especially suited for high-value items that require careful, precise handling, offering a sustainable, non-toxic solution for businesses committed to quality and eco-friendly practices.

Dry ice sublimation cleaning uses the rapid transition from solid to gas upon impact to lift dirt and contaminants off surfaces. This instantaneous gas transformation creates a powerful cleaning effect that removes debris without leaving any residue behind, ensuring a thorough, non-abrasive clean.

Zero-Residue, Eco-Friendly Cleaning Solution

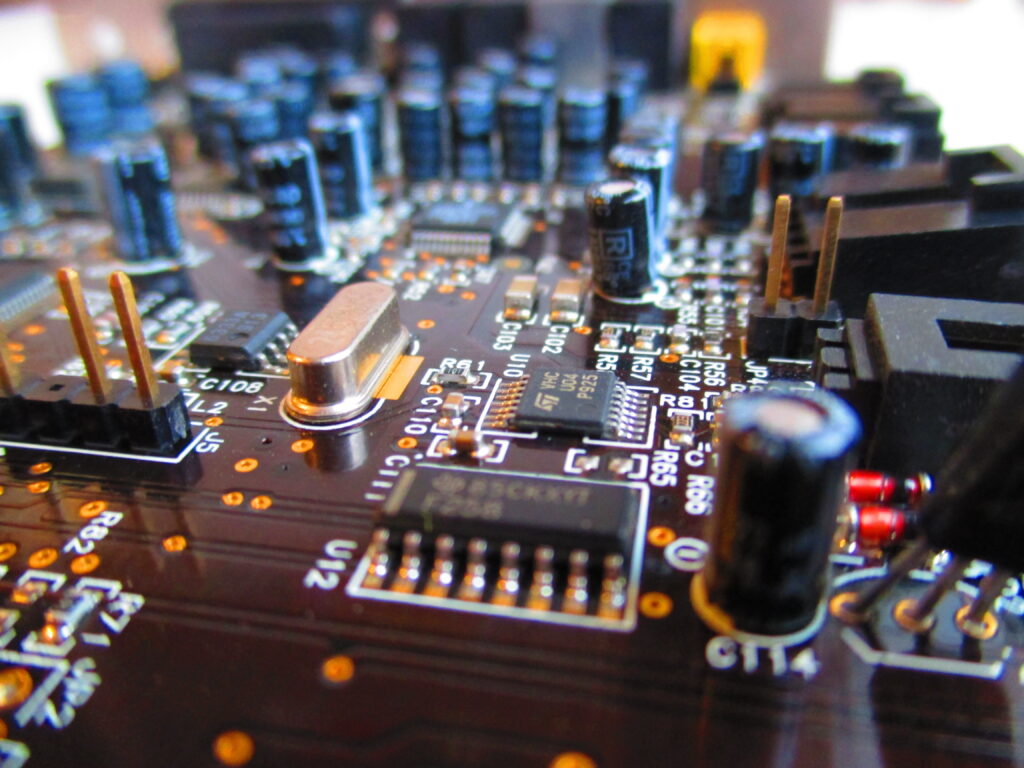

The sublimation process leaves no moisture, residue, or secondary waste, making it the ideal solution for moisture-sensitive environments. This method is especially effective in industries like electronics and food production, where residue-free cleaning is essential for maintaining operational efficiency and product integrity.

Dry Ice Blasting: Environmentally Friendly Surface Preparation Meeting Industry Standards Dry ice blasting is a highly effective, eco-friendly surface preparation method that meets or exceeds various industry-specific standards in New Zealand. This advanced cleaning technology is ideal for a range of industries, offering non-toxic, residue-free cleaning solutions that align with stringent regulatory requirements. Below are key industry standards where dry ice blasting demonstrates its superior performance:

NZS 5457:1986 – Ensures hygienic cleaning of food processing machinery.

AS/NZS 4674:2004 – Supports compliance with the design, construction, and fit-out requirements of food premises.

NZFSA Guidelines – Meets cleaning and sanitising standards for food processing equipment, conveyors, and surfaces, ensuring food safety.

NZS/AS 2885.1:2012 – Meets design and construction standards for gas and liquid petroleum pipelines.

API 510 – Adheres to in-service inspection, rating, repair, and alteration standards for pressure vessels.

AS/NZS 3750 Series – Meets standards for paints used on steel structures.

ISO 8501-1:2007 – Complies with visual assessment standards of surface cleanliness for steel substrates before painting.

AS/NZS 3788:2006 – Ensures integrity management and inspection of pressure equipment.

ISO 8501-1:2007 – Complies with steel substrate preparation standards before paint application.

NZS 4187:2014 – Complies with reprocessing standards for reusable medical devices in health service organisations.

ISO 14644-1:2015 – Meets cleanliness requirements for cleanrooms and controlled environments.

AS/NZS 2243.3:2010 – Adheres to laboratory safety standards, including microbiological aspects and containment facilities.

AS/NZS 2311:2009 – Meets painting guide standards for buildings.

NZS 3114:1987 – Complies with specifications for concrete surface finishes.

NZS 3101.1&2:2006 – Aligns with concrete structures standard.

AS/NZS 2312:2014 – Meets protective coating standards for structural steel against atmospheric corrosion.

AS 3894.10-2002 – Complies with abrasive blast cleaning site testing standards for protective coatings.

AS/NZS 1627.4:2005 – Aligns with abrasive blast cleaning standards for steel surfaces.

Elite Dry Ice is committed to delivering unparalleled cryogenic cleaning services across New Zealand. Based in Auckland, our brand stands for precision, expertise, and environmental responsibility, ensuring that businesses experience the highest standards of cleanliness without disruption.

At Elite Dry Ice, our mission is to provide superior cleaning solutions that meet the unique needs of each client. We strive to be the leading provider in New Zealand of dry ice blasting services, known for our exceptional skill level, outstanding results, and unwavering commitment to safety and sustainability.

Elite Dry Ice is more than just a cleaning service provider; we are a partner dedicated to enhancing the efficiency and safety of your operations. Our expertise and commitment to quality make us the preferred choice for businesses seeking premium cryogenic cleaning, dry ice blasting, surface cleaning, and industrial cleaning solutions.

Discover the Elite Dry Ice difference. Contact us today for a free quote and let us show you how our innovative cleaning services can benefit your business. Join the many satisfied clients who trust Elite Dry Ice for their cleaning needs.