Welcome to the pinnacle of industrial cleaning innovation. At Elite Dry Ice, we are setting new standards in cleanliness and efficiency through our innovative dry ice cleaning technology. This comprehensive article unveils the intricacies of this groundbreaking process, highlighting its myriad benefits, versatile applications, and its unquestionable superiority over conventional cleaning methodologies.

Traditional industrial cleaning methods have long grappled with issues like environmental impact, equipment wear, and operational downtime. Step forward dry ice cleaning, a revolutionary technique that harnesses solid CO2 pellets to deliver an unparalleled cleaning experience. With no need for chemicals or water, this technique is not just effective but also environmentally friendly, equipment-safe, and astonishingly efficient.

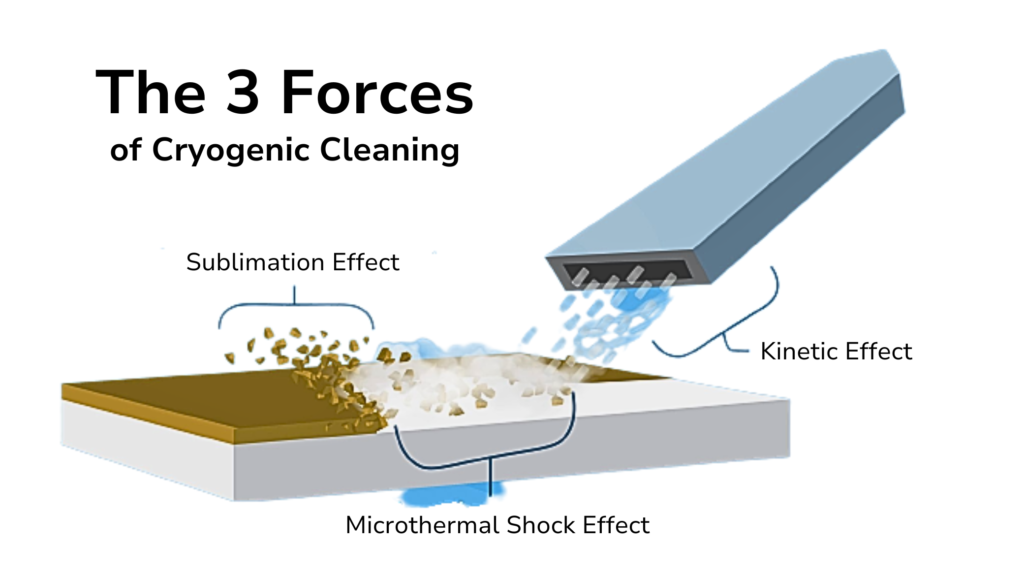

Dry ice cleaning also referred to as cryogenic cleaning, or dry ice blasting, functions on the principle of sublimation. By propelling compressed air-accelerated dry ice pellets onto surfaces, the pellets transform from solid to gas upon impact. This rapid phase change creates micro-explosions that dislodge contaminants such as grime, paint, and residues, leaving surfaces impeccably clean without any secondary waste generation.

Gentle yet Effective Cleaning: Unlike conventional methods that can damage delicate surfaces, cryogenic cleaning is gentle and non-abrasive. It preserves the integrity of sensitive equipment, extending its lifespan.

Eco-Friendly Solution: With cryogenic cleaning, there is zero water consumption, and the sublimation process means no residual waste is left behind. This makes it a sustainable choice, reducing environmental impact.

Unmatched Efficiency: Traditional cleaning methods often necessitate equipment disassembly, leading to operational downtime. Elite Dry Ice cleaning can be conducted in-situ, minimizing interruptions and maximising productivity.

Chemical-Free Approach: Chemical cleaning can leave behind harmful residues. Dry ice cleaning ensures a chemical-free, safe work environment.

The adaptability of cryogenic cleaning knows no bounds, making it a valuable asset across various industries:

Manufacturing And Fabrication: In the manufacturing sector, precision and quality are paramount. Elite Dry Ice cleaning efficiently removes contaminants like oils, grease, and debris from assembly lines, molds, and intricate components without causing damage.

Food And Beverage: Maintaining impeccable hygiene standards in the food and beverage industry is essential. Elite Dry Ice cleaning guarantees a thorough and effective cleaning process for equipment like conveyors, ovens, and packaging lines, reducing the risk of contamination.

Power Generation And Utilities: Power plants and utilities demand meticulous cleaning to ensure smooth operations. Elite Dry Ice cleaning effectively eliminates dirt, soot, and residues from generators, turbines, and electrical panels without abrasive effects.

As we stand at the forefront of industrial cleaning innovation, it is evident that dry ice cleaning is redefining the norms. At Elite Dry Ice, we are committed to delivering unparalleled cleaning solutions that optimise efficiency, minimise downtime, and uphold environmental responsibility. Join us in embracing a future that is cleaner, greener, and more efficient.

In summary, the era of conventional cleaning methods is waning, yielding ground to the extraordinary capabilities of dry ice cleaning. With its gentle yet potent cleaning action, eco-friendliness, and versatility across industries, this revolutionary technique is poised to revolutionise industrial cleaning practices. Make Elite Dry Ice your partner in this transformative journey toward elevated cleaning excellence.

Reach out to us today to explore how dry ice cleaning can reshape your industry, setting you on a trajectory to surpass competitors and achieve unparalleled success.