Don’t let dirty electronics cripple your operations. Discover how dry ice blasting from Elite Dry Ice Cleaning maximises uptime, minimises risk, and optimises performance. Get a FREE Consultation Today!

In today’s fast-paced world of electronics, downtime is costly. Maintaining peak performance requires meticulous cleaning, especially for delicate electrical kit. Enter dry ice blasting, a revolutionary cleaning technology that trumps traditional methods. Elite Dry Ice Cleaning is here to transform your electronics maintenance, ensuring optimal performance and minimising disruptions.

Unlike abrasive methods, dry ice (frozen CO2) is non-conductive and non-toxic, eliminating the risk of damage to delicate components and electrical safety hazards.

Dry ice sublimates (turns from solid to gas) upon contact, leaving no secondary waste or harmful residues.

Dry ice cleaning can clean in place (CIP) or requires minimal disassembly, significantly reducing equipment downtime compared to traditional methods methods like water-based cleaning or chemical solvents.

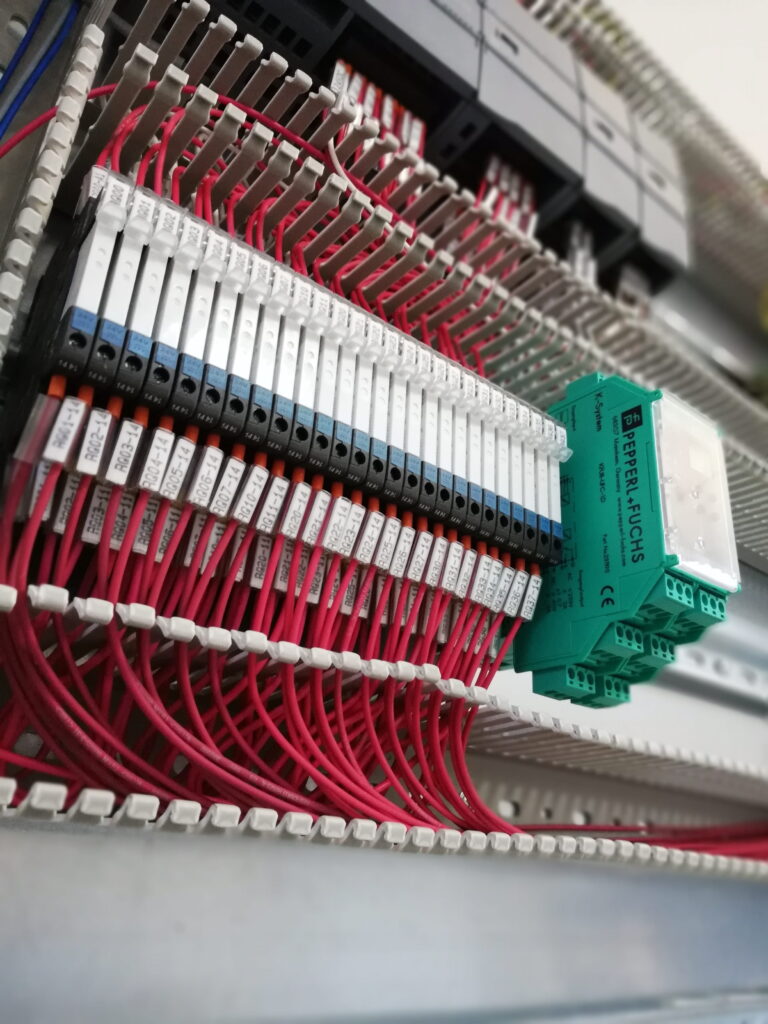

The pressurised CO2 blast reaches even the most intricate nooks and crannies, removing dirt, dust, contaminants, and even stubborn substances like grease and welding slag that traditional methods miss. This is crucial for preventing overheating, arcing, and other performance issues.

By removing contaminants that can cause overheating and arcing, dry ice cleaning significantly reduces the risk of catastrophic equipment failure in electronics and power generation systems. This translates to improved reliability and reduced maintenance costs.

Clean, contaminant-free surfaces ensure accurate and reliable megohm readings (a crucial indicator of electrical insulation health) in electronics. In power generation equipment, dry ice blasting cleans turbine blades and removes build-up that can hinder airflow, improving efficiency and power output.

Clean equipment operates cooler, improving thermal efficiency and extending component lifespan in both electronics and power generation applications. This translates to lower energy consumption and reduced operational costs.

Removes solder flux, dust, and other contaminants for

optimal performance.

Keeps critical equipment cool and operating efficiently.

Effectively removes dirt, grime, and grease build-up.

Maintains production line efficiency and reduces downtime.

Cleans and removes contaminants from transformer windings and bushings, improving efficiency and reducing the risk of arcing and flashovers. This translates to increased power transmission capacity and reduced maintenance costs.

Removes deposits and contaminants from turbine blades for improved efficiency and performance. This can include removing built-up salts, minerals, and combustion byproducts that can reduce airflow and hinder turbine operation.

Cleans and removes pollution and grime buildup, preventing electrical leakage and flashovers. Dry ice blasting is a safe and effective method for cleaning insulators on high-voltage transmission lines and substation equipment.

Removes dust, dirt, and other contaminants that can compromise the accuracy and reliability of control systems in power generation facilities.

Cleans and removes contaminants from electrical contacts and bus bars, improving conductivity and reducing the risk of arcing and overheating. This helps to ensure reliable power distribution and prevent equipment failure.

Removes dust, dirt, and debris from generator windings and commutators, improving efficiency and output.

Imagine the peace of mind knowing your electronics are operating at peak performance. Elite Dry Ice Cleaning can help you achieve this by removing contaminants that can lead to costly disruptions.

Don’t wait for a disaster to strike – proactive maintenance with dry ice cleaning is vital for optimal equipment longevity.

Ready to achieve peak performance in your electronics? Our team of experts is here to answer your questions and provide a FREE consultation. Contact us today by phone, email, or through our website to discuss your specific needs and discover how dry ice cleaning can revolutionize your electronics maintenance.